Sintered NdFeB

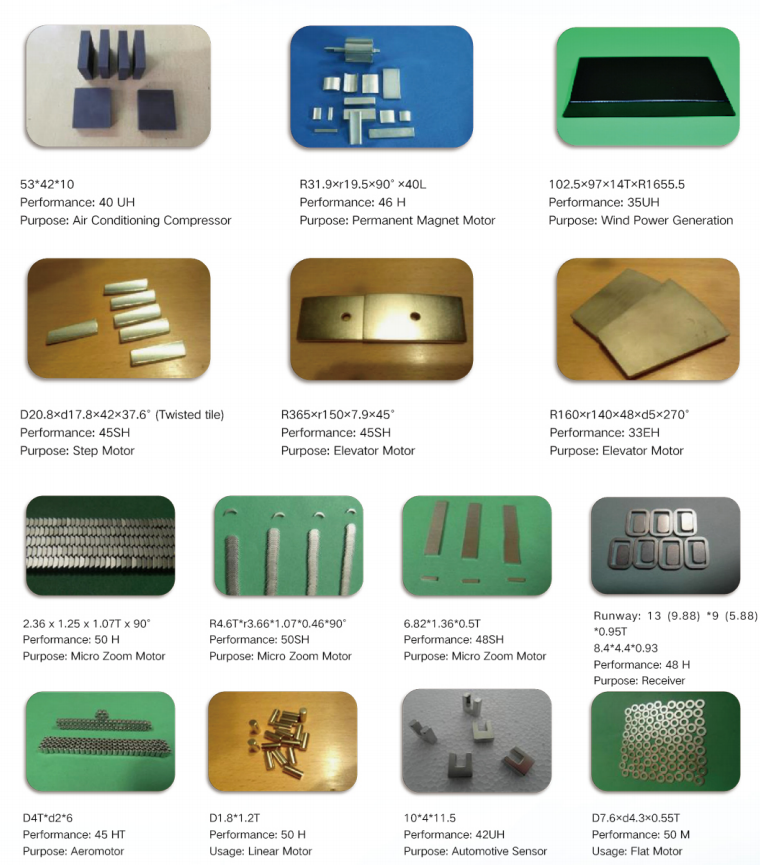

We produce high quality sintered NdFeB (N54,52SH, 50UH, 45EH, 40AH) mainly covering five fields: 1 Consumer Electronics, 2 Energy-saving Motors, 3 Micro motors, 4 Sensors, 5 Magnetic equipment. According to the product shape, it can be divided into: Cylinder type magnetic steel, ring/cake type magnetic steel, square type magnetic steel, special type magnetic steel.

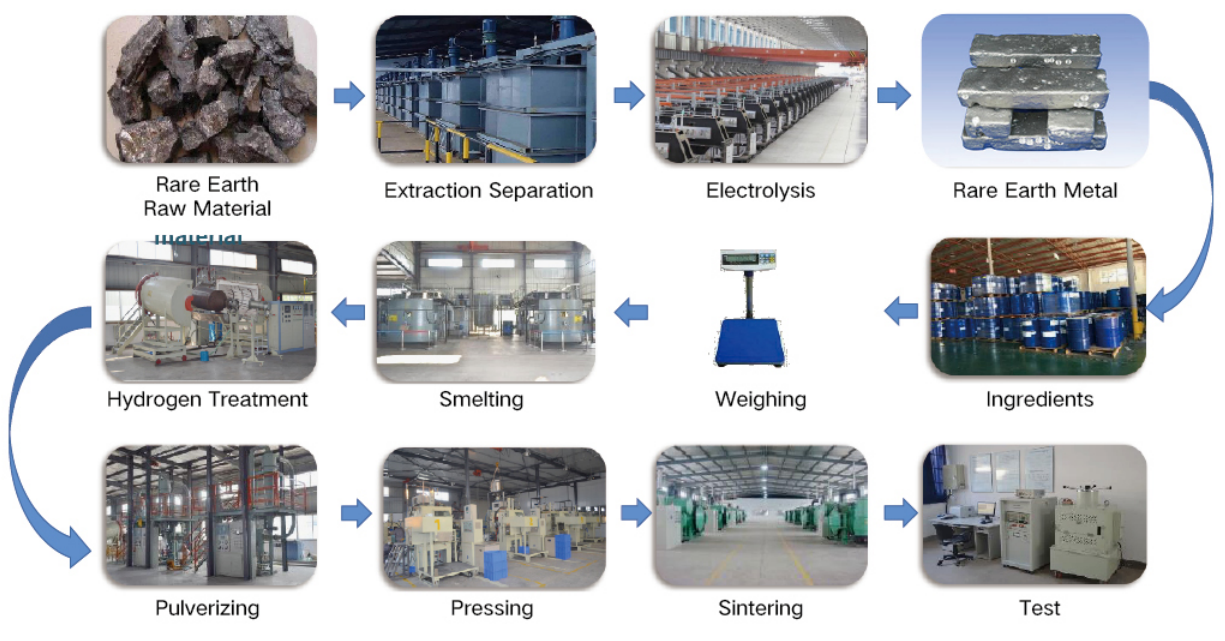

Blank Manufacturing Process

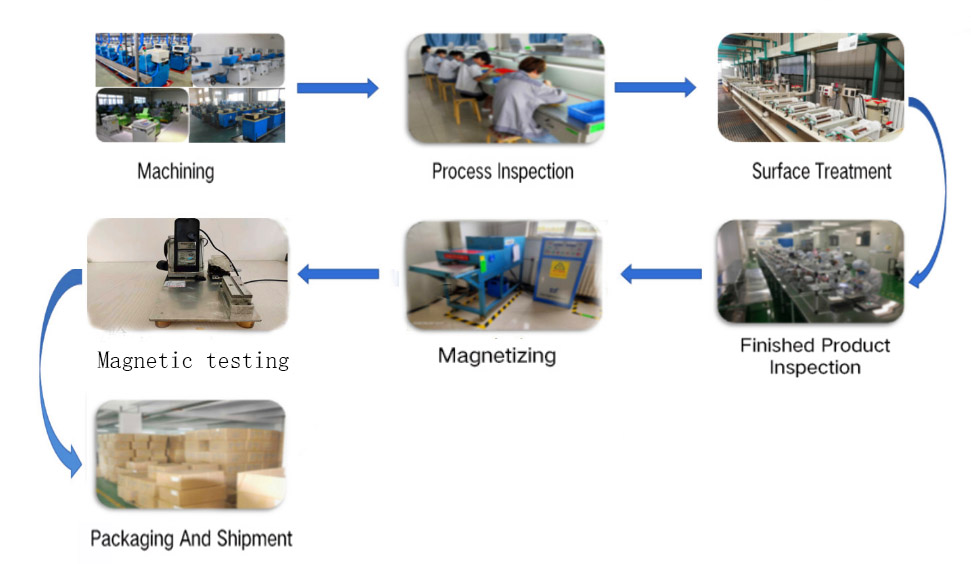

Sintered NdFeB Manufacturing Process

Common hysical Properties and Performance Parameters of Sintered NdFeB

| Br | Hcj |

Hcb | (BH)max | temperature coefficent | Max.operating temperature | density | ||||||||

| T | kGs | kA/m | kOe | kA/m | kOe | kJ/m3 | MGOe | a(Br) | a(Hcj) | (L/D=0.7)/℃ | g/cm3 | |||

| 1 | N | N35 | 1.17~1.22 | 11.7~12.2 | 955 | 12 | 868 | 10.9 | 263~287 | 33~36 | -0.12 | -0.7 | 80 | 7.45 |

| 2 | N38 | 1.22~1.27 | 12.2~12.7 | 955 | 12 | 899 | 11.3 | 287~310 | 36~39 | -0.12 | -0.7 | |||

| 3 | N40 | 1.25~1.30 | 12.5~13.0 | 955 | 12 | 923 | 11.6 | 302~326 | 38~41 | -0.12 | -0.7 | |||

| 4 | N42 | 1.28~1.34 | 12.8~13.4 | 955 | 12 | 923 | 11.6 | 318~342 | 40~43 | -0.12 | -0.7 | |||

| 5 | N45 | 1.33~1.38 | 13.3~13.8 | 955 | 12 | 876 | 11 | 342~366 | 43~46 | -0.12 | -0.7 | |||

| 6 | N48 | 1.37~1.43 | 13.7~14.3 | 955 | 12 | 892 | 11.2 | 366~390 | 46~49 | -0.12 | -0.7 | |||

| 7 | N50 | 1.39~1.45 | 13.9~14.5 | 876 | 11 | 836 | 10.5 | 374~406 | 47~51 | -0.12 | -0.7 | |||

| 8 | N52 | 1.42~1.47 | 14.2~14.7 | 876 | 11 | 836 | 10.5 | 390~422 | 49~53 | -0.12 | -0.7 | |||

| 9 | N54 | 1.44~1.48 | 14.4~14.8 | 876 | 11 | 900 | 11.3 | 406~438 | 51-55 | -0.12 | -0.7 | |||

| 10 | N56 | 1.46~1.50 | 14.6~15.0 | 876 | 11 | 900 | 11.3 | 422~454 | 53-57 | -0.12 | -0.7 | |||

| 11 | M | 35M | 1.17~1.22 | 11.7~12.2 | 1114 | 14 | 868 | 10.9 | 263~287 | 33~36 | -0.12 | -0.7 | 100 | 7.50 |

| 12 | 38M | 1.22~1.27 | 12.2~12.7 | 1114 | 14 | 899 | 11.3 | 287~310 | 36~39 | -0.12 | -0.7 | |||

| 13 | 40M | 1.25~1.30 | 12.5~13.0 | 1114 | 14 | 923 | 11.6 | 302~326 | 38~41 | -0.12 | -0.7 | |||

| 14 | 42M | 1.28~1.34 | 12.8~13.4 | 1114 | 14 | 955 | 12 | 318~342 | 40~43 | -0.12 | -0.7 | |||

| 15 | 45M | 1.33~1.38 | 13.3~13.8 | 1114 | 14 | 995 | 12.5 | 342~366 | 43~46 | -0.12 | -0.7 | |||

| 16 | 48M | 1.37~1.43 | 13.7~14.3 | 1114 | 14 | 1019 | 12.8 | 358~390 | 46~49 | -0.12 | -0.7 | |||

| 17 | 50M | 1.39~1.45 | 13.9~14.5 | 1114 | 13 | 1035 | 13 | 374~406 | 47~51 | -0.12 | -0.7 | |||

| 18 | 52M | 1.42~1.47 | 14.2~14.7 | 1035 | 13 | 995 | 12.5 | 390~422 | 49~53 | -0.12 | -0.7 | |||

| 19 | 54M | 1.44~1.48 | 14.4~14.8 | 1035 | 13 | 1000 | 12.6 | 406~438 | 51-55 | -0.12 | -0.7 | |||

| 20 | H | 35H | 1.17~1.22 | 11.7~12.2 | 1353 | 17 | 868 | 10.9 | 263~287 | 33~36 | -0.12 | -0.7 | 120 | 7.55 |

| 21 | 38H | 1.22~1.27 | 12.2~12.7 | 1353 | 17 | 899 | 11.3 | 287~310 | 36~39 | -0.12 | -0.7 | |||

| 22 | 40H | 1.25~1.30 | 12.5~13.0 | 1353 | 17 | 923 | 11.6 | 302~326 | 38~41 | -0.12 | -0.7 | |||

| 23 | 42H | 1.28~1.34 | 12.8~13.4 | 1353 | 17 | 955 | 12 | 318~342 | 40~43 | -0.12 | -0.7 | |||

| 24 | 45H | 1.33~1.38 | 13.1~13.8 | 1353 | 17 | 963 | 12.1 | 334~358 | 43~46 | -0.12 | -0.7 | |||

| 25 | 48H | 1.37~1.43 | 13.7~14.3 | 1353 | 16 | 971 | 12.2 | 342~366 | 45~49 | -0.12 | -0.7 | |||

| 26 | 50H | 1.39~1.45 | 13.9~14.5 | 1274 | 16 | 1035 | 13 | 374~406 | 47~51 | -0.12 | -0.7 | |||

| 27 | 52H | 1.42~1.47 | 14.2~14.7 | 1274 | 16 | 1059 | 13.3 | 390~422 | 49~53 | -0.12 | -0.7 | |||

| 28 | SH | 33SH | 1.13~1.18 | 11.3~11.8 | 1592 | 20 | 844 | 10.6 | 247~270 | 31~34 | -0.11 | -0.65 | 150 | 7.55 |

| 29 | 35SH | 1.17~1.22 | 11.7~12.2 | 1592 | 20 | 876 | 11 | 263~287 | 33~36 | -0.11 | -0.65 | |||

| 30 | 38SH | 1.22~1.27 | 12.2~12.7 | 1592 | 20 | 907 | 11.4 | 287~310 | 36~39 | -0.11 | -0.65 | |||

| 31 | 40SH | 1.25~1.30 | 12.5~13.0 | 1592 | 20 | 939 | 11.8 | 302~326 | 38~41 | -0.11 | -0.65 | |||

| 32 | 42SH | 1.28~1.34 | 12.8~13.4 | 1592 | 20 | 971 | 12.2 | 318~342 | 40~43 | -0.11 | -0.65 | |||

| 33 | 45SH | 1.32~1.38 | 13.2~13.8 | 1592 | 19 | 995 | 12.3 | 342~366 | 43~46 | -0.11 | -0.65 | |||

| 34 | 48SH | 1.36~1.42 | 13.6~14.2 | 1512 | 19 | 995 | 12.5 | 358~390 | 45~49 | -0.11 | -0.65 | |||

| 35 | 50SH | 1.39~1.45 | 13.9~14.5 | 1512 | 19 | 1019 | 12.8 | 374~406 | 47~51 | -0.11 | -0.65 | |||

| 36 | UH | 28UH | 1.02~1.08 | 10.2~10.8 | 1990 | 25 | 764 | 9.6 | 207~231 | 26~29 | -0.11 | -0.6 | 180 | 7.60 |

| 37 | 30UH | 1.08~1.14 | 10.8~11.4 | 1990 | 25 | 812 | 10.2 | 223~254 | 28~32 | -0.11 | -0.6 | |||

| 38 | 33UH | 1.13~1.18 | 11.3~11.8 | 1990 | 25 | 852 | 10.7 | 247~270 | 31~34 | -0.11 | -0.6 | |||

| 39 | 35UH | 1.17~1.22 | 11.7~12.2 | 1990 | 25 | 860 | 10.8 | 263~287 | 33~36 | -0.11 | -0.6 | |||

| 40 | 38UH | 1.22~1.27 | 12.2~12.7 | 1990 | 25 | 876 | 11 | 287~310 | 36~39 | -0.11 | -0.6 | |||

| 41 | 40UH | 1.26~1.30 | 12.6~13.0 | 1911 | 24 | 915 | 11.5 | 302~326 | 38~41 | -0.11 | -0.6 | |||

| 42 | 42UH | 1.30~1.35 | 13.0~13.5 | 1911 | 24 | 971 | 12.2 | 310~342 | 39~43 | -0.11 | -0.6 | |||

| 43 | 45UH | 1.32~1.38 | 13.2~13.8 | 1911 | 24 | 995 | 12.5 | 342~366 | 43~46 | -0.11 | -0.6 | |||

| 44 | 48UH | 1.36~1.42 | 13.6~14.2 | 1911 | 24 | 1019 | 12.8 | 358~390 | 45~49 | -0.11 | -0.6 | |||

| 45 | EH | 28EH | 1.04~1.09 | 10.4~10.9 | 2388 | 30 | 780 | 9.8 | 207~231 | 26~29 | -0.11 | -0.55 | 200 | 7.6 |

| 46 | 30EH | 1.08~1.14 | 10.8~11.4 | 2388 | 30 | 812 | 10.2 | 223~254 | 28~32 | -0.11 | -0.55 | |||

| 47 | 33EH | 1.13~1.18 | 11.3~11.8 | 2388 | 30 | 820 | 10.3 | 247~270 | 31~34 | -0.11 | -0.55 | |||

| 48 | 35EH | 1.17~1.22 | 11.7~12.2 | 2388 | 30 | 836 | 10.5 | 263~287 | 33~36 | -0.11 | -0.55 | |||

| 49 | 38EH | 1.22~1.27 | 12.2~12.7 | 2388 | 30 | 915 | 11.5 | 279~310 | 35~39 | -0.11 | -0.55 | |||

| 50 | 40EH | 1.26~1.30 | 12.6~13.0 | 2388 | 30 | 939 | 11.8 | 302~326 | 38~41 | -0.11 | -0.55 | |||

| 51 | 42EH | 1.30~1.35 | 13.0~13.5 | 2388 | 30 | 955 | 12 | 310~342 | 39~43 | -0.11 | -0.55 | |||

| 52 | AH | 28AH | 1.02~1.09 | 10.2~10.9 | 2706 | 34 | 780 | 9.8 | 199~231 | 25~29 | -0.1 | -0.5 | 230 | 7.65 |

| 53 | 30AH | 1.07~1.13 | 10.7~11.3 | 2706 | 34 | 812 | 10.2 | 215~247 | 27~31 | -0.1 | -0.5 | |||

| 54 | 33AH | 1.11~1.17 | 11.1~11.7 | 2706 | 34 | 820 | 10.5 | 239~271 | 30~34 | -0.1 | -0.5 | |||

| 55 | 35AH | 1.17~1.22 | 11.7~12.2 | 2706 | 34 | 860 | 10.8 | 263~287 | 33~36 | -0.1 | -0.5 | |||

16/5000

Products and Application

Product Layout

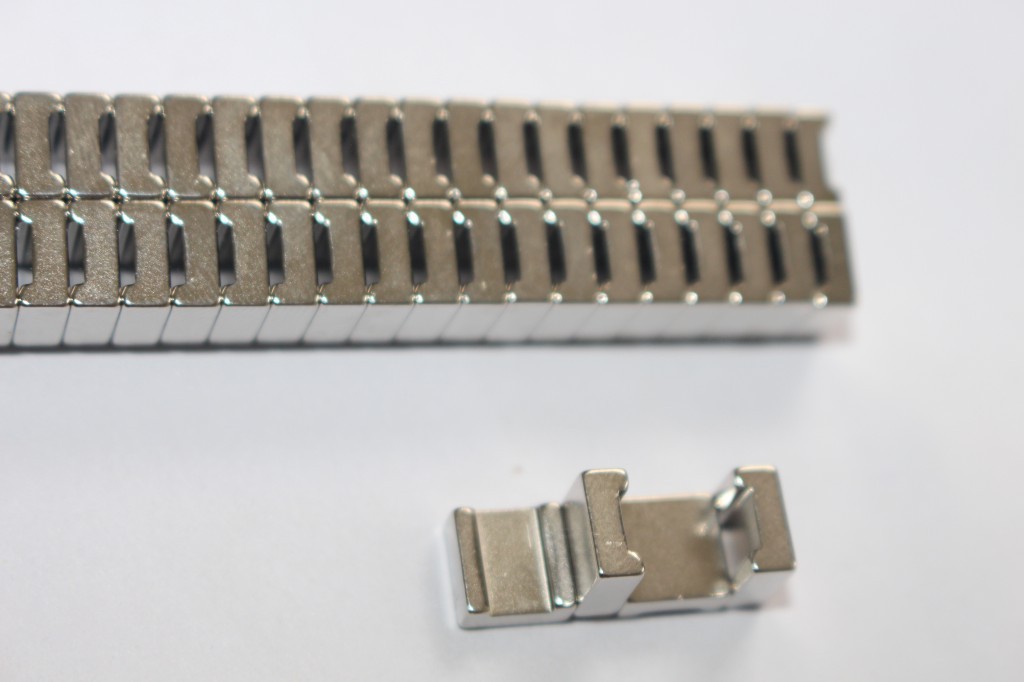

Cylinder type magnetic steel

Toroidal/pancake magnet

Square type magnetic steel

Special-shaped magnet